EV Batteries: The “High-End” Battle Between LFP and NCM

EV batteries are at the center of a heated debate in the electric vehicle industry: Which technology is superior—lithium iron phosphate (LFP) or nickel cobalt manganese (NCM)? At first glance, this appears to be a matter of chemistry. In truth, it reflects a deeper interaction of technological rivalry, industrial evolution, and consumer perception.

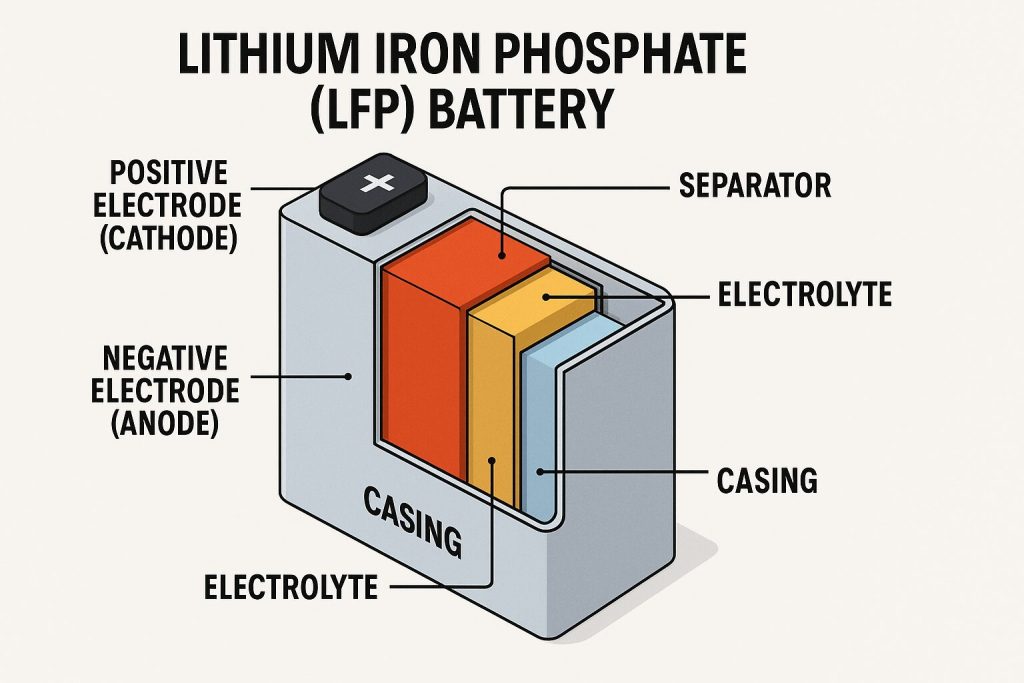

1. Fundamental Technical Differences

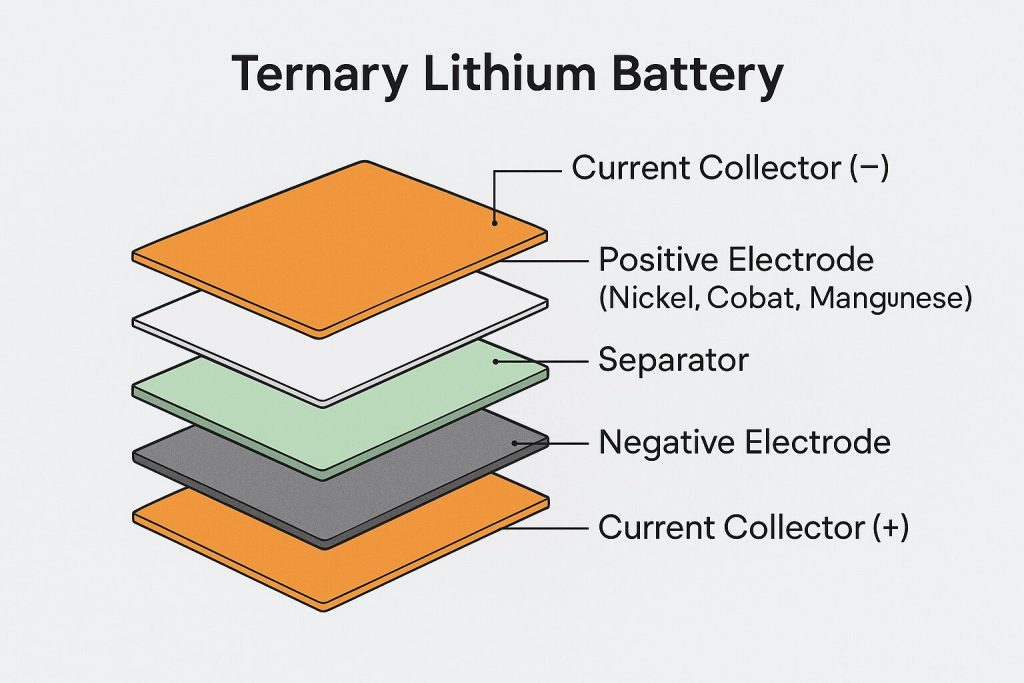

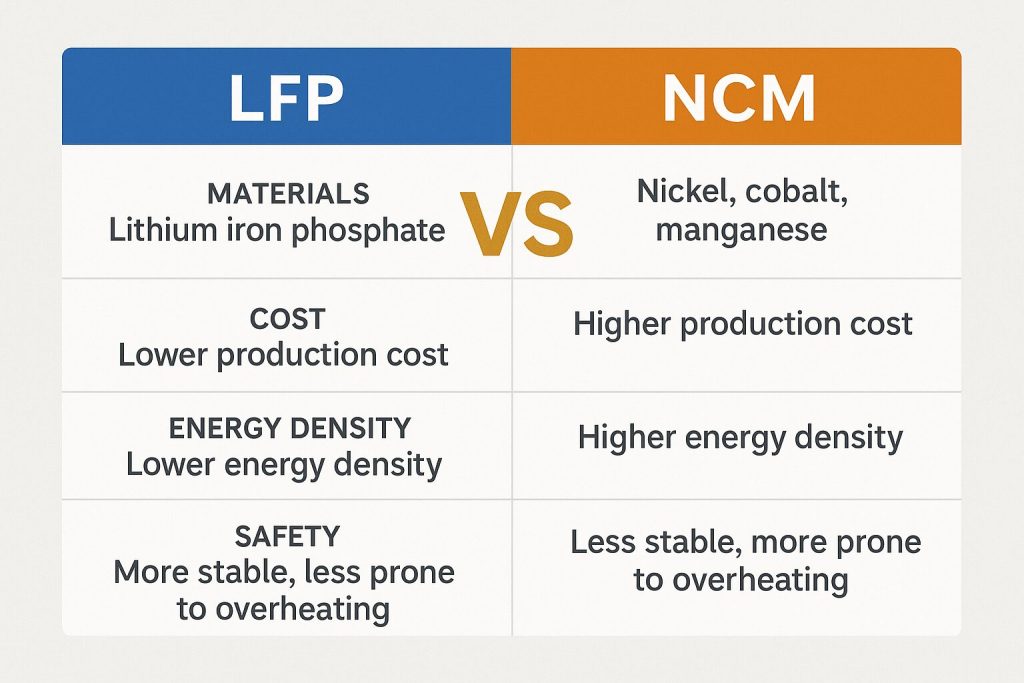

NCM batteries (nickel-cobalt-manganese) became the backbone of early EV development thanks to their high energy density, making long-range driving possible. However, their reliance on scarce metals like nickel and cobalt drives up costs and raises concerns about supply chain security and safety risks.

In contrast, lithium iron phosphate (LFP) batteries stand out for their safety, stability, and affordability. Their materials are abundant, and production costs are easier to control. While early versions lagged behind in energy density, LFP batteries have always carried the potential for sustainable large-scale application.

2. Breakthroughs Reshaping the Competitive Landscape

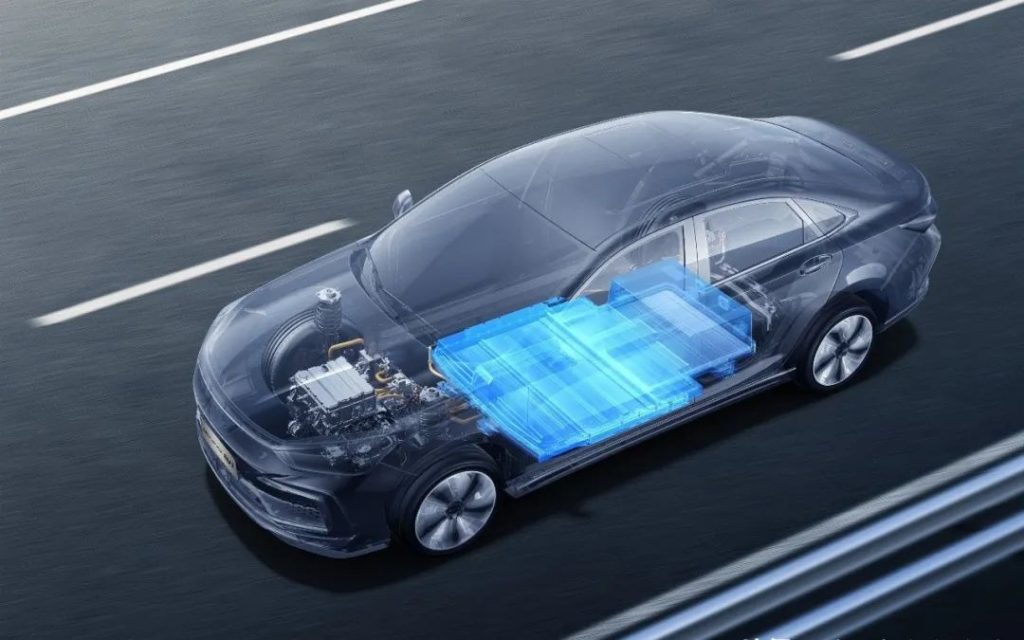

The turning point came with structural innovations. A prime example is BYD’s Blade Battery, which broke through the traditional limits of LFP. By optimizing cell-to-pack architecture and space utilization, its volumetric energy density increased significantly, pushing driving range closer to that of NCM batteries.

Beyond energy density, LFP batteries demonstrate clear advantages in extreme conditions:

- Stronger thermal stability under high-power output

- More stable discharge performance at low state of charge

- Safer operation during fast charging

- Extended cycle life

These attributes make LFP batteries highly competitive even in high-performance vehicles. The record-breaking speed of the Yangwang U9 supercar is proof of this capability.

3. Redefining the Meaning of “High-End”

A major misconception exists in today’s EV market: equating higher cost with higher quality.

Because NCM batteries use costly metals, their vehicles are often perceived as “premium.” But price alone is not a reliable measure of advancement.

A truly high-end EV battery system should be evaluated on four dimensions:

- Technological advancement – Does it represent the future of EV battery development?

- Safety and reliability – Can it guarantee driver confidence under all conditions?

- Adaptability – Does it meet the diverse needs of different driving scenarios?

- Sustainability – Is it resource-efficient and environmentally friendly?

From this perspective, LFP batteries are not “low-end” at all. On the contrary, they often demonstrate greater balance, safety, and sustainability, which are key features of what “high-end” truly means.

4. Deeper Reflections on Industry Development

The rivalry between NCM and LFP batteries is more than a competition of chemistry—it represents two development philosophies.

- NCM focuses on pushing the limits of performance.

- LFP emphasizes safety, resource accessibility, and scalable adoption.

With continued innovation, these two paths are starting to converge and borrow from each other. But one thing is clear: a battery technology based on resource security and safety aligns best with the long-term interests of the EV industry—especially in China.

Conclusion

In today’s fast-evolving automotive industry, it’s no longer appropriate to judge EV batteries with a static, price-based mindset.

The rise of lithium iron phosphate batteries proves that true “high-end” status doesn’t come from expensive materials, but from innovation, safety, and real-world value.

For consumers, this means breaking free from the “expensive equals better” bias and choosing based on practical needs and long-term reliability.

For the industry, the challenge is clear: continue to innovate and redefine “high-end” by creating products that are safe, reliable, adaptable, and sustainable.

In the end, the real winner of the EV battery “battle” will not be one specific chemistry, but the technology philosophy that best meets consumer needs and drives sustainable industry growth.

If you have a need to buy a car, or if you run a car business, we’re here to help. As a leading exporter with over 20 years of experience, DDong Used Cars offers a wide range of vehicle brands (100+), efficient logistics, and after-sales support.

Contact us today to learn more. Simply let us know what you’re looking for, and we’ll provide you with an unmatched sourcing experience. Explore our news section for more automotive insights and tips for running a successful dealership.

Frequently Asked Questions (FAQs)

1. Which EV battery is better: LFP or NCM?

It depends on usage. LFP batteries are safer, more affordable, and longer-lasting, while NCM batteries deliver higher energy density and longer driving range.

2. Do EV batteries degrade over time?

Yes. All EV batteries lose capacity gradually. On average, most EV batteries retain 70–80% capacity after 8–10 years, depending on driving habits and climate.

3. Are LFP EV batteries really safer than NCM?

Yes. LFP batteries are more thermally stable, making them less prone to overheating or catching fire, especially under extreme conditions.

4. Why are NCM EV batteries more expensive?

Because they rely on nickel, cobalt, and manganese, which are costly and subject to supply chain volatility.

5. How long can EV batteries last?

Most EV batteries last 1,500–3,000 charging cycles, which equals about 300,000–500,000 km of driving, depending on technology and usage.

6. What is the future trend for EV batteries?

The industry is moving toward hybrid approaches, such as combining LFP’s safety with structural innovations to boost density, while exploring solid-state batteries for the next generation of EVs.